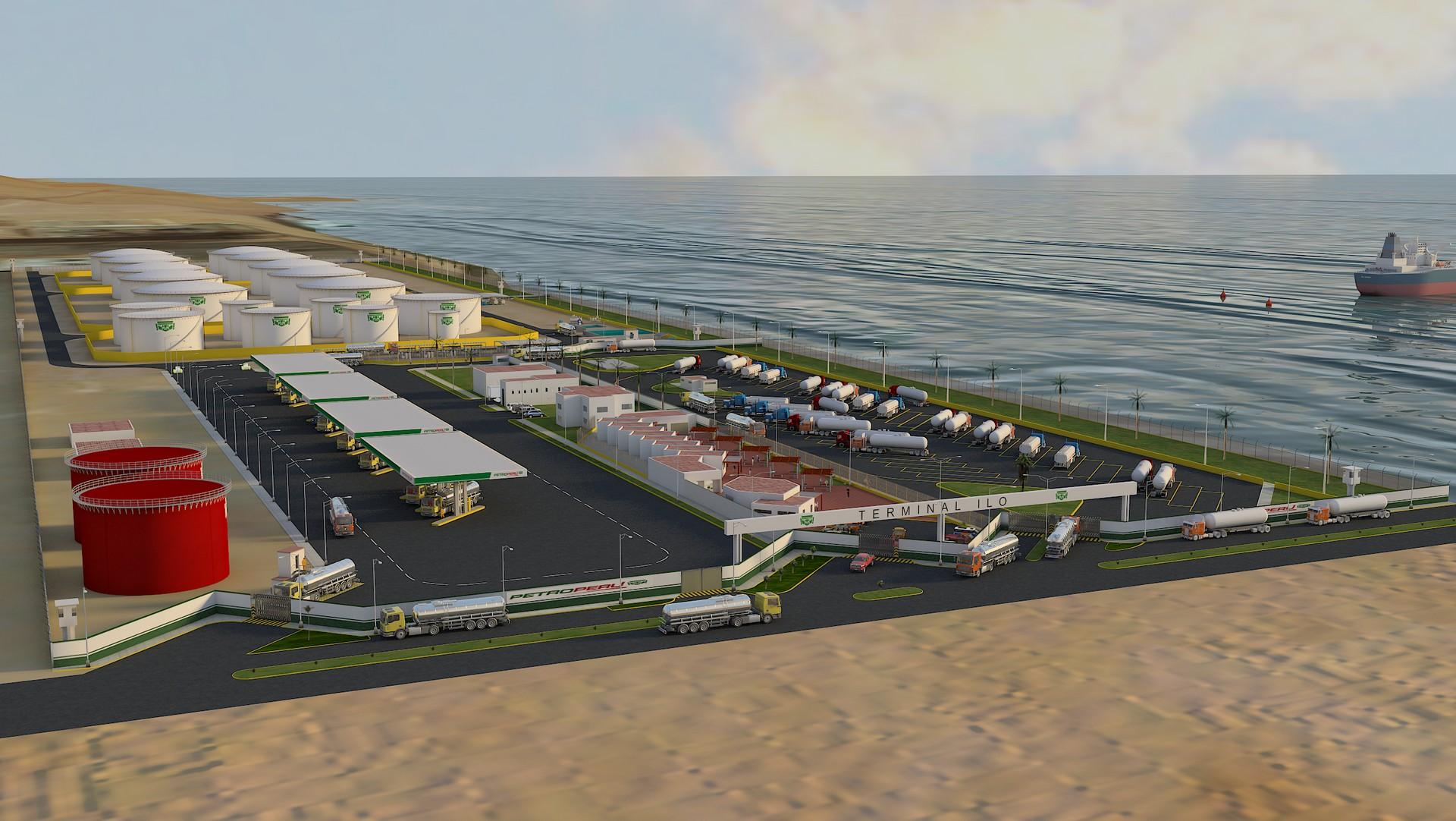

New Ilo Terminal

Objective

Installation and Operation of a New Terminal in the city of Ilo that allows to satisfactorily meet the current and projected demand of liquid fuels for its area of influence, constituted by the Moquegua and Tacna regions, with prospects to additionally meet the demand of the regions Puno and Madre de Dios. The project has as scope the reception, storage, transfer and dispatch of the following fuels: Diesel B5, Diesel 2E, Gasohol 84, Gasohol 90 and Gasohol 95.

Location

The new Terminal will be located in the area called Loma La Buitrera, district and province of Ilo - Moquegua region (24 kilometers south of the city of Ilo). It will be located in an area of 164,128.20 m2.

Descripción

The project consists of the construction, installation and start-up of a New Supply Terminal in Ilo, to meet the demand for liquid fuels destined for the area of influence. The scope of the project is the reception, storage, transfers and dispatch of the following fuels: Diesel B5, Diesel 2E, Gasohol 84, Gasohol 90 and Gasohol 95.

Reception: multi-buoy berth for unloading made up of 3 submarine lines (diesel, gasoline and ethanol), to market white products. The reception by ships to the multi-buoy berth will be designed so that ships of up to 60,000 DWT can operate.

Storage: in its first stage, the New Ilo Terminal will have a storage capacity of 293 MBls of liquid hydrocarbons (7 tanks), to later expand its storage capacity to 1050 MBls (18 tanks).

Dispatch to tanker trucks: it will initially have 16 loading arms (initial stage) to later expand to 19 (second expansion). These bottom loading arms will serve tanker trucks up to 11,000 gallons. The system also includes online additives.

Other facilities:

Product transfer system from the storage tanks to the sales area will be made up of centrifugal-type electric pumps with an explosion-proof motor.

Instrumentation, monitoring and control, with state-of-the-art technology for the reception, storage and dispatch of fuels, firefighting systems, effluent and waste system, surveillance system, terminal dispatch, billing, among others.

Firefighting system consisting of vertical steel tanks with aluminum dome for water and bladder tanks for foam; distribution network, valves, accessories and foam generation chambers.

Industrial drainage system, freshwater system, electrical facilities (electrical substation connected to the public network, diesel generator set, lightning rod).

Plant area is delimited and protected by a wall of noble material along its perimeter, interior tracks for circulation and parking areas paved with asphalt.

Roofed areas for fire pump house, dispatch pump station, power room and warehouses. Buildings for administrative offices, bank office, sales offices, laboratory, dining room, sentry boxes and watchtowers.